Blog 1 (Laser Cutting)

Greetings everyone!! Welcome to my first blog👀😇 and hope y'all are having a good day. In this blog, I will be sharing with y'all about what I learnt during the laser cutting practical😱😱. So lets get right into it!

This is the contents I will be going through today:

- The 4 important hazards associated to the operation of the laser cutting machine and their respective safety control measures (administrative/engineering control).

- The materials that can be cut and can't be cut using the laser cutting machine.

- The steps including pictures on the operation of the UNIVERSAL laser cutter.

- Learning reflection about the laser cutting activities.

Before I start, let me show you an illustration of a typical laser cutting setup so that you can roughly understand how will it work. The computer will send instruction to the laser cutter to cut your design. The fume extractor and air compressor are safety measures to remove smoke and debris during the laser cutting.

During the operation of the laser cutting machine, there are hazards you should look out for to prevent any accidents from happening. Let me give you 4 examples of the hazards and the ways to prevent them from happening so that everyone can be safe when operating the laser cutting machine.

1. These are the 4 important hazards and the respective safety control measures on the operation of the laser cutting machine:

After knowing some of the hazards of the laser cutter, you might wanna know more about what the laser cutter can cut and can't.

2. Below are the materials that can be cut/engraved using the laser cutter machine in FabLab:

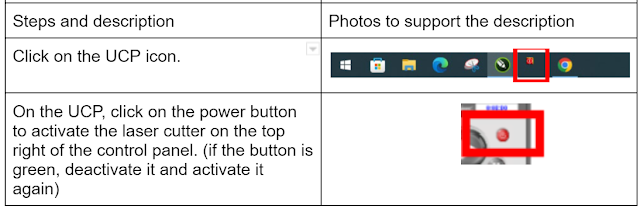

3. Below are the steps on the operation of the UNIVERSAL laser cutter machine in FabLab:

a. Starting the compressor, turning on the laser cutting machine and the fume extractor.

c. Sending the Coreldraw drawing to laser cutter software and setting the laser cutter power, speed, PPI in the software.

d. Starting the job on the laser cutter machine.

4. Below is my reflection on the laser cutting activities

On the tutorial session day itself, I was really tired as it was an 8am class and it was a Monday. When the class start, Mr Chua announced that we will be having a practical about our competency in laser cutting on Wednesday and therefore he is going through some lesson package about laser cutting. During the tutorial session I learnt many things such as vector vs raster where vector is the image staying clear as ice when zoomed in and raster is the image getting pixelated when zoomed it. Some raster examples in our daily lives are the camera picture that we take and when we zoom them in, it gets pixelated. I also remember vividly that Mr Chua mention that Mr Mark is a very serious teacher and if we do something wrong we will fail the competency test.

About 10minutes before the test, I would like to thank my classmate Mr Ryan Phua for giving me tips on what he was tested after he finished and passed the test. The tips he gave me really helped me in the test later. When it was my turn for the competency test, I quickly entered the room and started the test. When Mr Mark was giving us the guide he did it so smoothly and easily that I thought that it would actually be an easy test. However, when I was operating the computer, I was actually having some trouble clicking on the line color as I did not know I had to double click and therefore I was stuck for a while. I was also confused which outline that should be cut out and which one to engrave. I was glad that I managed to operate the UCP smoothly and quickly print out my sussy emoji.

In the end, I came in clutch and finish the test just when the 10 minute timer rang. The guide that Mr Mark gave us really helped me learnt a lot more and pass the test as it is face to face which makes it easier for me to understand. Looking back when I was doing the competency test, if I am given a chance again, I can definitely hit under 10 minutes as I know what my mistakes are and how to correct them. These skills that I learnt in laser cutting are useful and can be implemented in the future if I am ever going to use a laser cutter again.

You have come to the end of this week's blog. Thank you for reading. See you next week. Goodbye!👋

Comments

Post a Comment